Solutions & Services

Quality Makes Us Global

Global Forming’s commitment to quality means better results for every customer.

Comprehensive planning and a customer-centric collaborative approach to every project not only ensures the highest quality possible for the final product, but also efficient operations from beginning to end for on-time delivery and cost savings.

Automotive Industry Expertise

HVAC Metal Manufacturing

Global Forming manufactures a variety of metal components for heating, ventilation, and air conditioning (HVAC) systems. Among the most common HVAC metal components we’ve handled are louvres and louvre panels. Assemblies for HVAC systems are accomplished through a range of fastening techniques see our Assemblies page for more information.

Building and Construction Industry

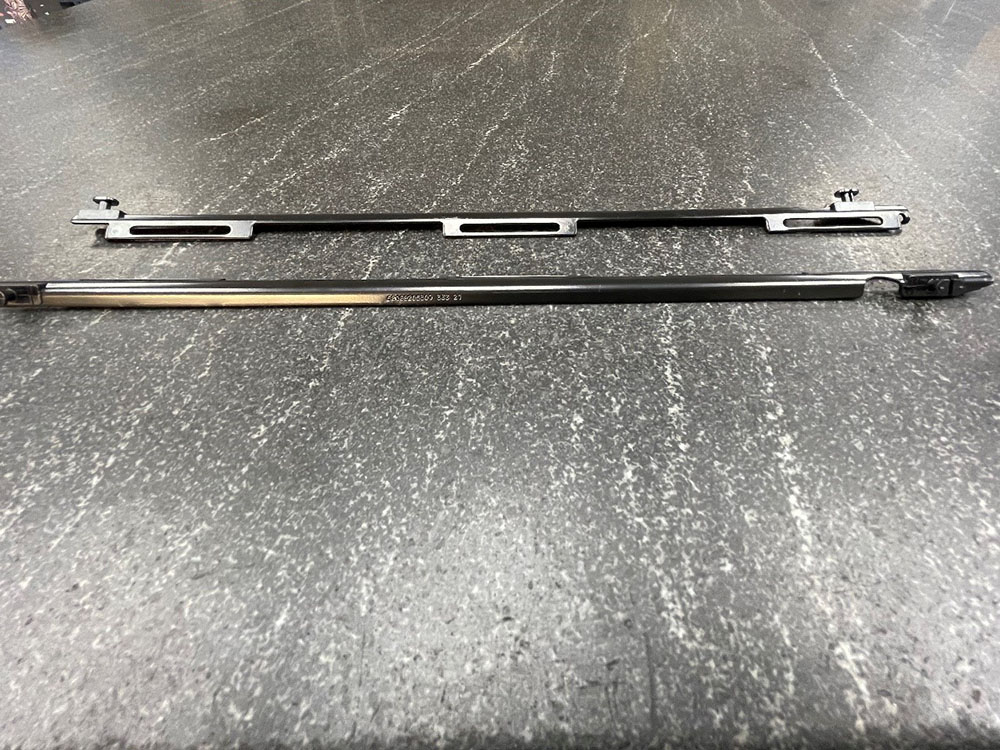

Global Forming’s metal shaping experience and state-of-the-art equipment are uniquely suited to manufacturing building exit devices needed on many doors, typically referred to as push bars, panic bars, and crash bars. Originally developed for quick egress during emergency situations, push bars are commonly installed on building doors even when not required by building codes.

Custom High-Volume Metal Fabrication

Global Forming can work with customers from any industry to collaboratively meet their metal shaping needs with our range of high-volume capabilities, including roll forming, stamping, and stretch bending, along with welding and other assembly methods as needed.

Metal + Plastic Component Assemblies

As part of the Global family of companies, we can work directly with Global Plastics to assemble components made up of both plastic and metal parts. Their experience in plastic injection molding and blow molding combined with our expertise in metal forming and Assembly means you get everything you need under the Global umbrella rather than working with separate vendors and all the coordination that would require.