Welding

Quality Makes Us Global

Capabilities

Integrated Welding Manufacturing Solutions at Global Forming

Once a metal part or component has been shaped by a manufacturing process such as roll forming, it often requires welding to properly finish it. Global Forming offers integrated welding manufacturing solutions to bring your metal component or part to completion with durability in mind.

The Right Welding Process for Your Metal Component

Spot Welding with Multi-Gun Capabilities

While the strength of the spot weld subtype of resistance welding is lower than other welding processes, it is often the perfect fit for joining metal sheets up to 3mm thick. Two copper alloy electrodes are used to send electrical currents through the layers of sheet metal with concentrated pressure and high heat. This welding process produces very little pollution, is highly energy-efficient, is fast for high production rates, does not require any filler materials, and can be easily and seamlessly automated. It is especially useful for corners and thin materials.

Spot welding can be used on sheet metals, aluminum alloys, nickel alloys, and titanium. When it comes to steel, low carbon (mild) steel and stainless steel (austenitic and ferritic grades), are best suited to spot welding as high carbon steel is prone to poor fracture toughness and cracking in the welds with spot welding. It is used in industries such as automotive, aerospace, rail, white goods, metal furniture, electronics, medical, and construction. With multi-gun equipment, we can perform multiple welds with one machine and minimal operator interaction to reduce operating costs and achieve faster production rates.

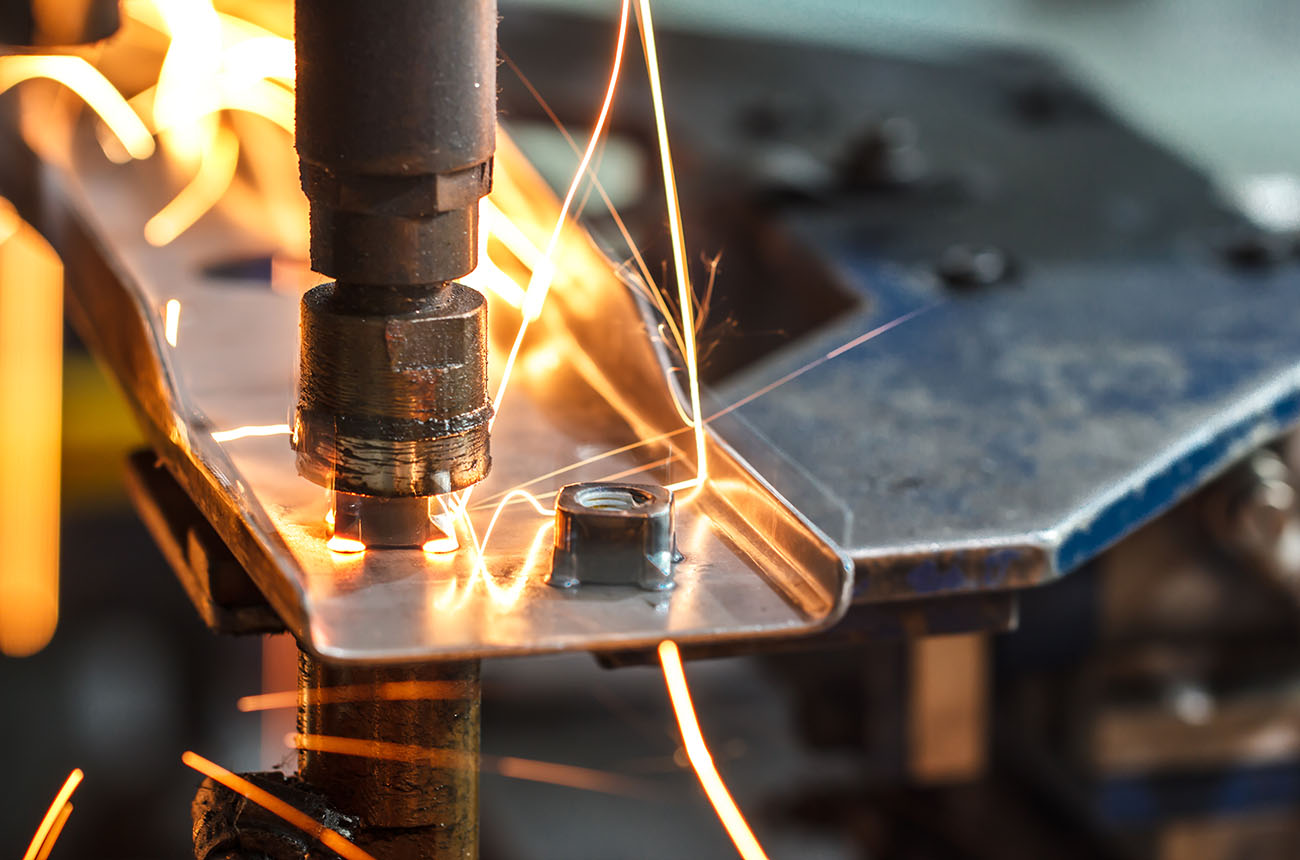

Multi-Gun Projection Welding

In addition to adhering two pieces of steel together, it can also be used to weld a nut, threaded stud, or projection to an assembly. Projection welding is commonly used in a wide range of applications, including automotive, consumer goods, mechanical (such as securing fasteners to components), construction, and semiconductors. Our multi-gun equipment allows us to perform multiple welds with one machine and minimal operator interaction to reduce operating costs and achieve faster production rates.

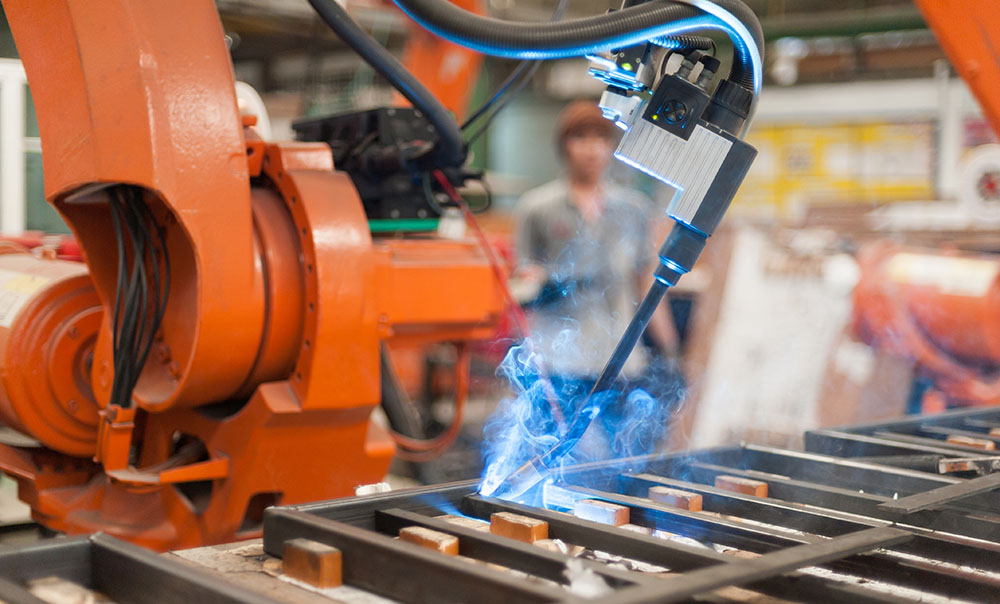

This welding technique is fast, versatile, and easily automated. It creates strong welds that can withstand high forces. This is why it’s popular in automotive and sheet metal applications. An inert gas such as argon or helium may be used (but not for nonferrous metals) or semi-inert gas such as carbon dioxide, or even a mix of inert and semi-inert (such as mixing argon and carbon dioxide) is used as a shielding gas to prevent atmospheric gases from contaminating the weld. As a process, MIG welding is fast and can be adapted to both fully automatic and semi-automatic production lines. Its versatility has made it useful in other industries such as construction, branding, maritime applications, and robotics. Adjusting the shielding gases makes MIG welding possible on non-ferrous metals such as aluminum, but also on various steels and even some super alloys.

Because this welding process uses non-consumable tungsten electrodes, it does require the use of filler. It’s advantage over MIG welding is that the equipment can take higher temperatures, which make it especially well-suited for welding thin sections of stainless steel. It is also used on aluminum, magnesium, copper alloys, titanium, copper, and brass. The result is a precise, high-quality weld with good aesthetic appearance.

Laser beam welding has been growing in popularity because of how powerful and versatile it is. It can be used in automotive applications, aerospace applications, and just about everything in between. A focused laser beam has a very high-energy density, which allows it to produce deep welds while also reducing the size of weld areas. When combined with automation and robotics, laser welding achieves incredible precision, repeatability, speed, and reliable high-quality results. Global Forming has invested in laser welding and automation equipment so you don’t have to. Its versatility allows it to be used on a wide range of materials at different thicknesses.

The beauty of laser welding is that its precision means you’ll never have to do any post-welding operations such as additional grinding. Smooth welds? No problem. Deep weld seams? Easy. Laser welding can literally do it all, and without any extra reworking. It’s the best shortcut that saves production line time while getting high-quality results. In fact, a laser welded seam is every bit as strong as the welded material, and in many cases even stronger, which means the material itself will tear before the laser weld tears.

Because of how fast laser welding is compared to other welding techniques, it’s often not as expensive as many think it will be. The one caveat, of course, is that fixtures for holding the pieces must be constructed. Simplicity in welding fixtures should be the goal to keep those costs down, as well as adapting old fixtures to new purposes whenever possible. Rest assured Global Forming will ensure fixture construction cost is minimized as much as possible while maintaining the integrity of the process. Our laser welding equipment is manufactured by Trumpf ©, a global market and technology leader in laser equipment for industrial manufacturing, including laser welding systems.

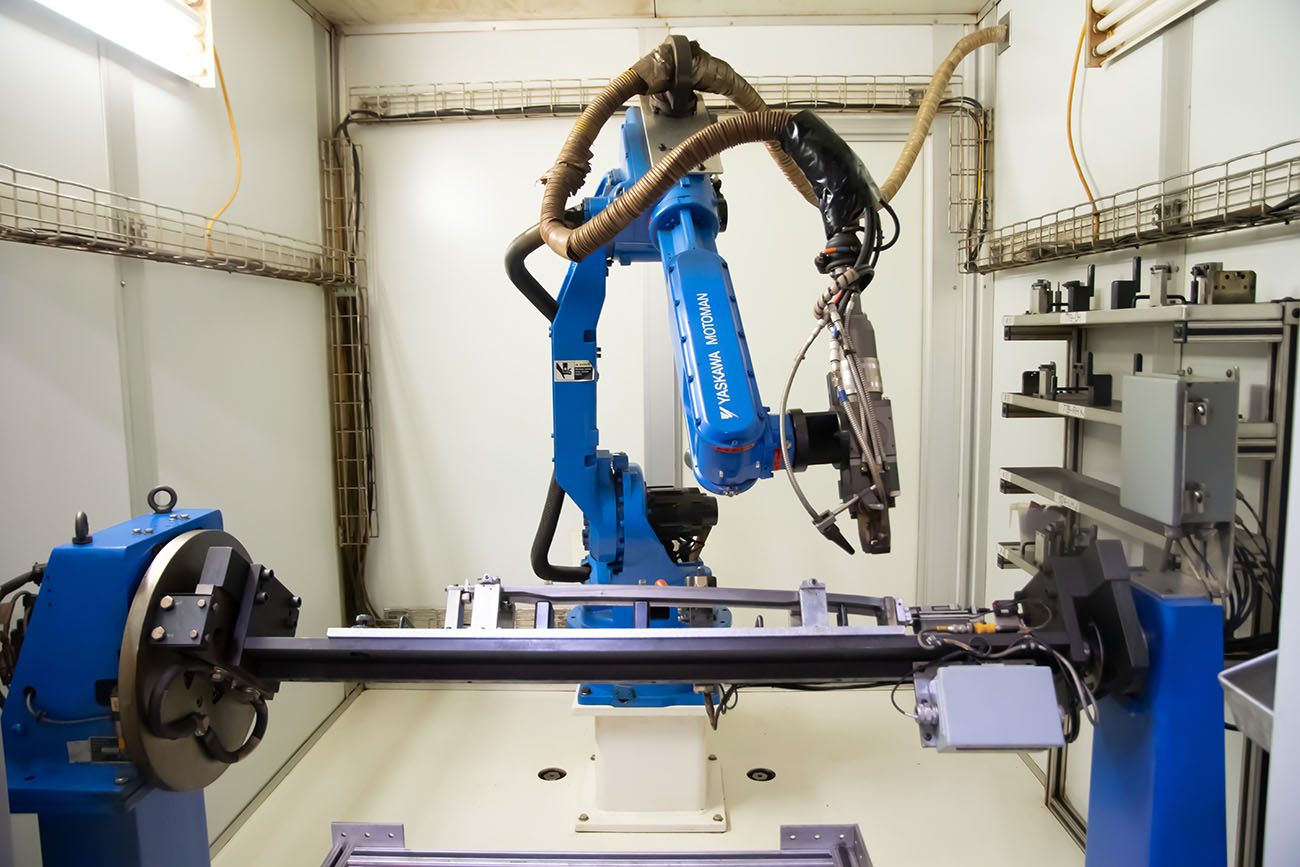

The ultimate in welding manufacturing automation is utilizing robotics to wield the welding equipment for the precision and repeatability that can only be achieved by machines. Simply put, compared to handheld guns and fixed machinery, robotic welders can deliver greater consistency and faster cycle times. Robotics can be applied to arc welding, resistance welding (spot and projection), and laser welding. At Global Forming we use robotic welding equipment made by Yaskawa Motoman Robotics ©, a leading industrial robotics company in the Americas.

Whether your business needs welded metal components in the United States or shipped around the world, Global Forming has the high-quality welding expertise and equipment needed to provide the integrated metal shaping and welding solution you need. Our welding manufacturing approach evaluates what type of welding process will meet your needs and requirements, and to provide the service as quickly, efficiently, and cost-effectively as possible. We look forward to discussing your metal shaping and welding needs. Get in touch with Global Forming through the contact us page, call us directly at 317.290.1000 to start the conversation and get a quote for our services.